|

researchers at duke university are developing conductive ink-jet printer inks using metal nanoparticles suspended in liquids to print inexpensive circuit patterns on any surface and without the need for heat to make sure that they work.

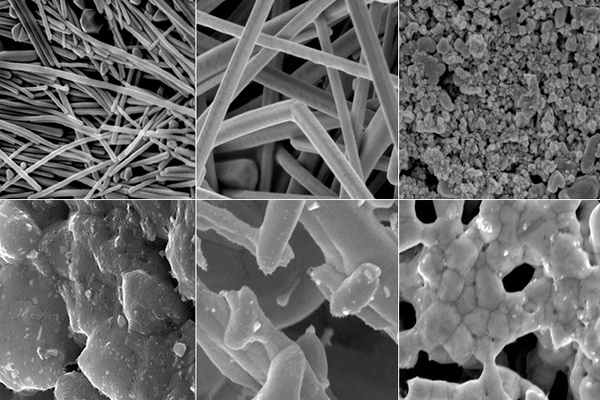

researchers used silver nanowire films to create printed electronics. (ian stewart)

the researchers determined that electrons move quicker through films composed of silver nanowires than films made from other nanostructures. the silver nanowire films could conduct electrons without the need for heat to melt them together. in fact, the nanowires had conductivity that was 4,000 times as high as other silver nanoparticles used in printed antennas such as radio frequency identification (rfid) tags.

without the need for heat, the expectation is that this could lead to the printing of electronic circuits on cheaper materials such as plastics or paper, according to an article on the duke website. this could lead to applications beyond smart packaging, including solar cells, led, touchscreens, and batteries, among others.

long nanowires were expected to have high conductivity because they avoid the necessary jumps that electrons would have to make between unconnected films. next on the list of experiments is using aerosol jets to print silver nanowire inks in usable circuits and to test whether or not silver-coated copper nanowires, which would be less expensive, would have similar qualities.

the research was recently published in applied materials and interfaces. the abstract stated:

“the relatively high temperatures (>200 °c) required to sinter silver nanoparticle inks have limited the development of printed electronic devices on low-cost, heat-sensitive paper and plastic substrates. this article explores the change in morphology and resistivity that occurs upon heating thick films of silver nanowires (of two different lengths; ag nws), nanoparticles (ag nps), and microflakes (ag mfs) at temperatures between 70 and 400 °c.

“after heating at 70 °c, films of long ag nws exhibited a resistivity of 1.8 × 10–5 ω cm, 4000 times more conductive than films made from ag nps. this result indicates the resistivity of thick films of silver nanostructures is dominated by the contact resistance between particles before sintering. after sintering at 300 °c, the resistivity of short ag nws, long ag nws, and ag nps converge to a value of (2–3) × 10–5 ω cm, while films of ag mfs remain ∼10× less conductive (4.06 × 10–4 ω cm).

“thus, films of long ag nw films heated at 70 °c are more conductive than ag np films sintered at 300 °c. adding 10 wt % nanowires to a film of nanoparticles results in a 400-fold improvement in resistivity.”

|