|

researchers at the university of erlangen-nuremberg (fau) in germany have taken a step forward in the process of creating diamond foils for practical applications by creating the a foil with a diameter of 28 cm, the size of a pizza, which makes it the largest in the world, according to a press release from the university.

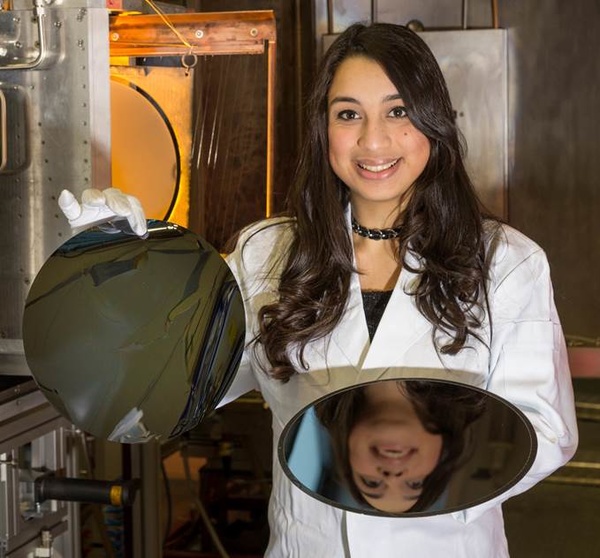

the world’s largest diamond foil is the size of a pizza. (fau)

the goal for the scientists is to make diamond foils as wear protection in industrial applications and to continue research into thermoelectric power generation. diamonds feature a number of mechanical properties that make them attractive for this research, including extreme hardness, wear resistant, chemical inertness, and thermal conductivity.

the research group grew the diamond foils on a silicon substrate. the foils were produced in a test reactor over several days and a 40-micrometer layer was grown in a low-pressure atmosphere of hydrogen and two percent methane. the foil grew under wires heated to 2,000°c and, after coating the disc, was hit with a pulse laser to create a circular fracture site into the surface.

“this makes it possible to separate the deposited layer as a very smooth diamond foil from the silicon substrate,” the article explained.

scientists developed the process so that they can adjust the diamond grain size and the foil’s electrical and thermal conductivity. they hope that this new technique will demonstrate the ability to scale-up the process of creating diamond foils.

the article noted, “virtually any substrate material can be coated with diamond film by means of a suitable joining technique. the extremely hard and smooth diamond foils can, for example, protect component surfaces against wear and tear.”

among the potential applications for diamond foils are protecting water turbines from sand erosion, coating industrial components, and producing stable diamond electrodes for water purification and disinfection systems.

the initial research that led to this recent development was published in two reports. the first, “mechanical properties of micro- and nanocrystalline diamond foils”, was published in physical transactions of the royal society of mathematical physical and engineering science in 2015. the abstract stated:

“diamond coating of suitable template materials and subsequent delamination allows for the manufacturing of free-standing diamond foil. the evolution of the microstructure can be influenced by secondary nucleation via control of process conditions in the hot-filament chemical vapour deposition process.

“bending tests show extraordinarily high strength (more than 8 gpa), especially for diamond foils with nanocrystalline structure. a detailed fractographic analysis is conducted in order to correlate measured strength values with crack-initiating defects. the size of the failure causing flaw can vary from tens of micrometres to tens of nanometres, depending on the diamond foil microstructure as well as the loading conditions.”

the second, entitled “thermoelectric transport properties of boron-doped nanocrystalline diamond foils”, was published in carbon in 2015. its abstract stated:

“natural diamond is known for its outstanding thermal conductivity and electrical insulation. however, synthetic production allows for doping and tailoring microstructural and transport properties. despite some motivation in the literature and the ongoing search for abundant and non-toxic thermoelectric materials, the first experimental study on a set of eight substrate-free boron-doped nanocrystalline diamond foils is presented herein.

“all transport coefficients were determined in the same direction within the same foils over a broad temperature range up to 900 degrees c. it is found that nanostructuring reduces the thermal conductivity by two orders of magnitude, but the mobility decreases significantly to around 1 cm(2) v-1 s(-1), too.

“although degenerate transport can be concluded from the temperature dependence of the seebeck coefficient, charge carriers notably scatter at grain boundaries where sp(2)-carbon modifications and amorphous boron-rich phases form during synthesis. a detailed analysis of doping efficiency yields an acceptor fraction of only 8-18 at%, meaning that during synthesis excess boron thermodynamically prefers electrically inactive sites.

“decent power factors above 10(-4)w m(-1) k-2 at 900 degrees c are found despite the low mobility, and a jonker-type analysis grants a deeper insight into this issue. together with the high thermal conductivity, the thermoelectric figure of merit zt does not exceed 0.01 at 900 degrees c.”

|