|

in recent years, the study of nanofluids has expanded its reach from a handful of university laboratories to companies across the globe. in the november 2 issue of applied sciences, a team of researchers from the university of sherbrooke (canada) explored the laminar forced convection of nanofluids flows through numerical simulations.

examining nanofluids flows through numerical simulations. (wikimedia commons)

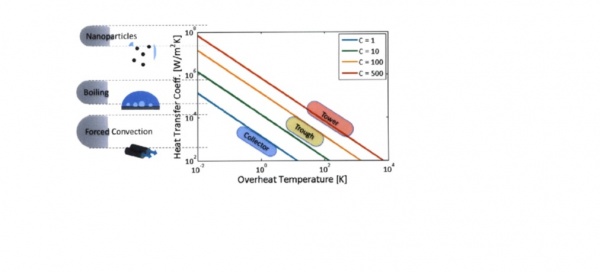

the study examined several nanofluid compositions in a uniformly heated round pipe and tested the thermal conductivity of each of the fluids. the mixture of copper and water had the highest heat transfer coefficient, according to the report.

the abstract of the findings stated:

“in the present paper, laminar forced convection nanofluid flows in a uniformly heated horizontal tube were revisited by direct numerical simulations. single and two-phase models were employed with constant and temperature-dependent properties. comparisons with experimental data showed that the mixture model performs better than the single-phase model in the all cases studied.

“temperature-dependent fluid properties also resulted in a better prediction of the thermal field. particular attention was paid to the grid arrangement. the two-phase model was used then confidently to investigate the influence of the nanoparticle size on the heat and fluid flow with a particular emphasis on the sedimentation process.

“four nanoparticle diameters were considered: 10, 42, 100 and 200 nm for both copper-water and alumina/water nanofluids. for the largest diameter dnp=200 nm, the cu nanoparticles were more sedimented by around 80%, while the al2o3 nanoparticles sedimented only by 2.5%. besides, it was found that increasing the reynolds number improved the heat transfer rate, while it decreased the friction factor allowing the nanoparticles to stay more dispersed in the base fluid.

“the effect of nanoparticle type on the heat transfer coefficient was also investigated for six different water-based nanofluids. results showed that the cu-water nanofluid achieved the highest heat transfer coefficient, followed by c, al2o3, cuo, tio2, and sio2, respectively.

“all results were presented and discussed for four different values of the concentration in nanoparticles, namely φ=0, 0.6%, 1% and 1.6%. empirical correlations for the friction coefficient and the average nusselt number were also provided summarizing all the presented results.”

read the full study at http://www.mdpi.com/2076-3417/6/11/332/htm.

|