|

researchers at stanford university have spent several years examining the problem of overheating batteries and the potential safety hazards that stem from the standard liquid electrolytes in lithium-ion batteries. from fire retardants added to the electrolytes to smart batteries with sensors to indicate that they were overheating, researchers have tried to find a way to ensure the safety of users.

stanford researchers are exploring ways to make batteries safer. (stanford university)

in january 2016, stanford researchers announced another potential solution using nanotechnology. they created nanoparticles of nickel protruding with microscopic spikes that were coated with graphene. the particles were then embedded into a thin film of elastic polyethylene and attached to the electrode of a battery so that electrical current would flow through it.

as an article on the stanford website explained, in order for the nanoparticle spikes to conduct electricity they needed to be in contact with each other. as temperatures increased, the polyethylene stretched and pulled the particles apart. at a certain level, the particles could no longer conduct electricity.

the researchers heated the battery to more than 70°c and the spikes separated and immediately the battery shut down. once the temperature lowered to 70°c, the battery started up again. researchers said that the temperature levels can be “tuned” depending on the number of particles or the polymer materials chosen.

in order to demonstrate that the battery performance would not suffer from the shutoff process, researchers used a hot air gun to heat the battery and then allow it to cool and conduct electricity again.

this january, stanford researchers were at it again with a new breakthrough that can expand the safety element of batteries by releasing a flame retardant as soon as the battery reaches a critical temperature, according to an ars technica article.

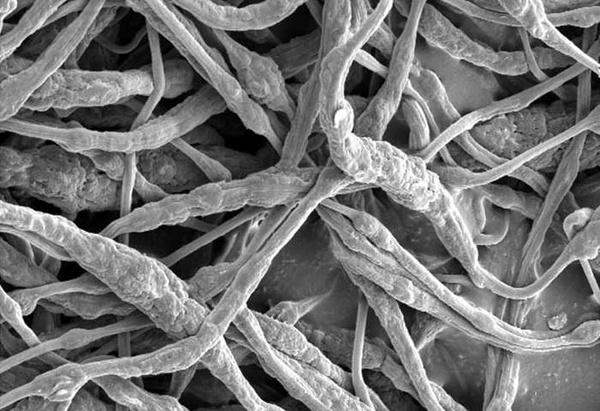

expanding on last year’s work with common polyethylene, the researchers have turned to fibrous threads of triphenyl phosphate (tpp) inside a shell of pvdf-hfp that prevents the retardant leaking into the electrolyte and harming the battery’s performance.

the article explains that when the separator hits 160°c (above the melting point of pvdf-hfp), the polymer melts and releases tpp into the electrolyte ton put out the fire. experiments showed that this process was successful in 0.4 seconds.

the recent work was published in science advances. the abstract stated:

“although the energy densities of batteries continue to increase, safety problems (for example, fires and explosions) associated with the use of highly flammable liquid organic electrolytes remain a big issue, significantly hindering further practical applications of the next generation of high-energy batteries.

“we have fabricated a novel ‘smart’ nonwoven electrospun separator with thermal-triggered flame-retardant properties for lithium-ion batteries. the encapsulation of a flame retardant inside a protective polymer shell has prevented direct dissolution of the retardant agent into the electrolyte, which would otherwise have negative effects on battery performance.

“during thermal runaway of the lithium-ion battery, the protective polymer shell would melt, triggered by the increased temperature, and the flame retardant would be released, thus effectively suppressing the combustion of the highly flammable electrolytes.”

|