|

researchers at sandia national laboratories have developed a new process for creating ultrafine-grained ceramic coatings by slamming high-velocity submicron ceramic particles onto a surface at room temperature, avoiding the need for high temperatures (regularly 700°c or more) that ceramic coatings typically require.

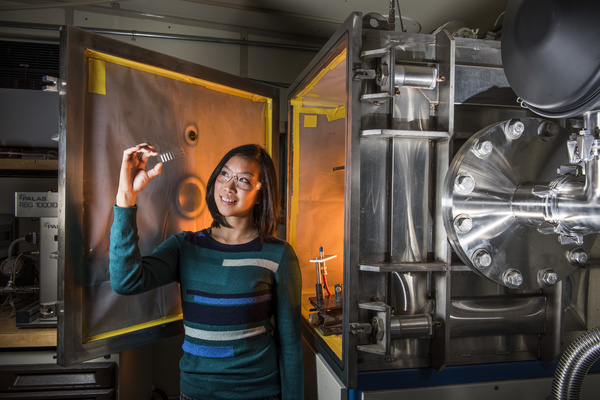

researcher pylin sarobol looks at samples of carbide coatings at sandia labs. (sandia national laboratories)

the kinetic process that was developed at sandia labs creates strong nanocrystalline films that could be used as protective coatings against corrosion, oxidation, and more. also, the temperature-based process that was previously used, forced engineers to avoid putting coatings on materials with low melting points.

as an article on the sandia labs website explained, “coating at room temperature makes microelectronics design and fabrication more flexible and could someday lead to better, less expensive microelectronics components that underpin modern technology.”

the research team used aerosol deposition to place the coatings. it is a process that is still being explored and there are concerns about the properties of the coatings, which are composed of nanocrystalline structures that are not usable in many applications, but adding heat will change those properties and tune the material to meet the application needs.

the article said, “in aerosol deposition, a nozzle accelerates submicron particles suspended in a gas toward the surface. particles impact and stick, building up a coating layer by layer…it’s the plasticity of submicron particles that causes consolidation of subsequent deposition layers and generates the continuous surface that layers are built upon.”

it was also critical for the process to take place in a vacuum to avoid bow shock, a gas boundary layer that would be difficult for smaller particles to penetrate. in a vacuum that layer is small enough for the submicron particles to break through.

the plasticity of the particles created tighter bo9nds as the nanoparticles hit the surface of the substrate. as the particle hits the surface, it changes shape and microfractures are created. when the next particle hits and deforms, it pushes down on the original layer to create a tighter bond.

the team has shown the ability to use several different materials, from copper to nickel to aluminum oxide, and insists that this method can be used to create capacitors, resistors, inductors, and more.

“the process also spans the microscale gap between two established technologies, thin films and thermal spray technology,” the article concluded. “thin films are coating layers, ranging in size from nanometers to a few microns, which can be defined into precision electrical circuits and are patterned via photolithography techniques instead of traditional printed circuit boards. thermal spray technology can produce coatings starting at about 50 microns up to a few centimeters.”

|