|

researchers, led by professor roger howe at stanford university, used previously abandoned satellite-powering technology and graphene instead of metal to develop a prototype energy converter that is almost seven times more efficient, according to a report from elsevier.

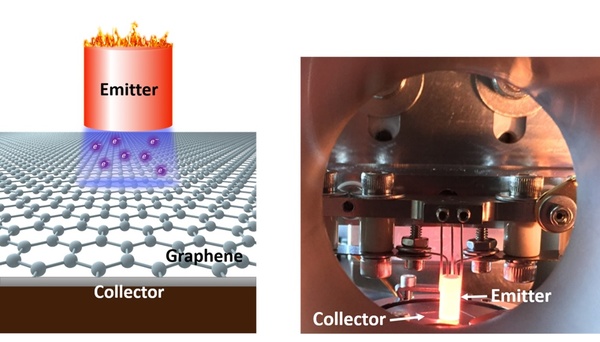

schematic sketch of the thermionic energy convertor prototype with a graphene collector (left)( and a photograph of

the tec prototype during operation in the stanford lab (right). (elsevier)

the researchers hope that this will reignite interest in thermionic energy conversion to reduce the amount of fossil fuels required for electricity production. according to the article, more than 80 percent of electricity generated in the u.s. comes from mechanical heat engines and turbines, but the thermionic energy converter (tec) can change that.

“the tec is composed of two electrodes, namely the emitter and collector, separated by a small vacuum gap,” the article explained. “the researchers tested a prototype tec made using a single sheet of carbon atoms – graphene – instead of tungsten as the collector material. they found the new material improved the efficiency of the tec, making it 6.7 times more efficient at converting heat into electricity at 1000?c.”

previous concerns about high energy loss at the anode surface that reduces voltage and the electrical barriers against electrons moving across the gap between collector and emitter have hampered developments of tec in the past but researchers demonstrated an electrical efficiency in energy conversion of 9.8 percent at 1,000°c.

this technology was originally developed in the 1950s for the space program but it was not efficient enough for an industrial scale. now, researchers see this breakthrough as applicable in power stations, for solar energy, and potentially for converting electricity from water boilers to power homes.

the future for tec is bright even if the prototype has only shown effectiveness in a vacuum chamber, but the researchers are working on tests to see if the technology works in real-world environments.

“this prototype is just the first step – there is a lot more to do,” said dr. hongyuan yuan of stanford university. “but our results so far are promising and reflect a happy marriage between modern materials science and an old-fashioned energy technology, which provides a route for re-sparking the field of thermionic energy conversion.”

the research was recently published in nano energy. the abstract stated:

“thermionic energy converters (tecs) are a direct heat-to-electricity conversion technology with great potential for high efficiency and scalability. however, space charge barrier in the inter-electrode gap and high anode work function are major obstacles toward realizing high efficiency.

“here, we demonstrate for the first time a prototype tec using a back-gated graphene anode, a barium dispenser cathode, and a controllable inter-electrode gap as small as 17 µm, which simultaneously addresses these two obstacles.

“this leads to an electronic conversion efficiency of 9.8% at cathode temperature of 1000 °c, the highest reported by far. we first demonstrate that electrostatic gating of graphene by a 20 nm hfo2 dielectric layer changes the graphene anode work function by 0.63 ev, as observed from the current-voltage characteristics of the tec.

“next, we show that the efficiency increases by a factor of 30.6 by reducing the gap from 1 mm down to 17 µm, after a mono-layer of ba is deposited on graphene by the dispenser cathode. finally, we show that electrostatic gating of graphene further reduces the graphene work function from 1.85 to 1.69 ev, leading to an additional 67% enhancement in tec efficiency.

“note that the overall efficiency using the back-gated graphene anode is 6.7 times higher compared with that of a tec with a tungsten anode and the same inter-electrode gap.”

|