|

engineers from the university of massachusetts amherst have reported modeling results for electrical surface treatment of conducting thin films as a processing method to reduce surface roughness, according to an announcement from the american institute of physics (aip).

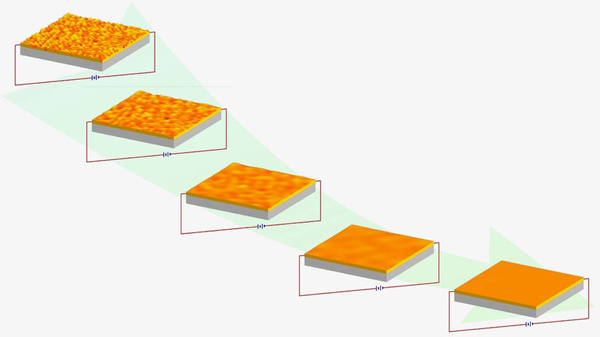

sequence of snapshots from a computer simulation of electric-field-driven morphological evolution of a

copper thin film, demonstrating current-induced smooth surface. (du and maroudas)

surface roughness is a critical factor for the building of electronic and optical devices. as components continue to shrink in size and component-density within integrated circuits continues to rise, smooth metallic lines are required as interconnections between the devices and the smoothness of those lines can have a significant effect on the thermal and electrical conductivity.

the umass researchers focused on copper films on a silicon nitride layer. the principle concept involved in the study is surface electromigration, which is the directed transport of atoms through the electron wind force that is an expression of the transfer of momentum from the electrons of the metal under an electrical field.

dimitrios maroudas, co-author and a professor in the department of chemical engineering, explained, “the combined effects of a well-controlled applied electric field and rough surface geometry drive the atoms on the metal surface to move from the hills of the rough surface morphology to the neighboring valleys, which eventually smooth away the rough surfaces.”

this technique is significantly different than previous processes such as mechanical polishing or ion-beam irradiation because it directly influences the diffusion of surface atoms and offers precision. it provides a smooth surface down to the atomic level.

“it can be used for fabricating and processing nanoscale-thick metallic components within electronic and optical devices, which require atomic-scale smoothness,” maroudas said. “the ability to reduce the surface roughness of metallic components, such as interconnects within integrated circuits, will significantly improve their performance as well as durability and reliability.”

the work was recently published in applied physical letters. the abstract stated:

“thin film surface roughness is responsible for various materials reliability problems in microelectronics and nanofabrication technologies, which requires the development of surface roughness reduction strategies.

“toward this end, we report modeling results that establish the electrical surface treatment of conducting thin films as a physical processing strategy for surface roughness reduction. we develop a continuum model of surface morphological evolution that accounts for the residual stress in the film, surface diffusional anisotropy and film texture, film's wetting of the layer that is deposited on, and surface electromigration.

“supported by linear stability theory, self-consistent dynamical simulations based on the model demonstrate that the action over several hours of a sufficiently strong and properly directed electric field on a conducting thin film can reduce its surface roughness and lead to a smooth planar film surface.

“the modeling predictions are in agreement with experimental measurements on copper thin films deposited on silicon nitride layers.”

|