|

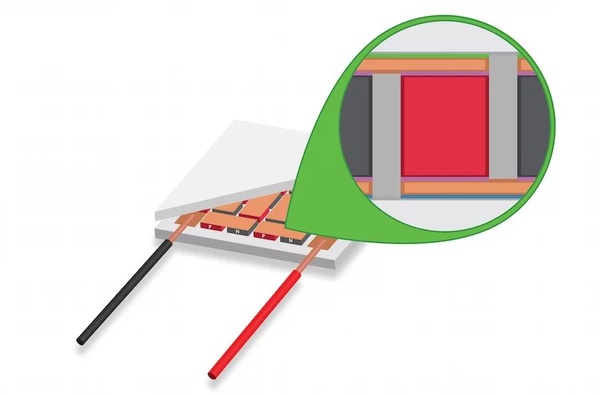

the thermal management group at cui, inc. announced that it has developed a new line of peltier thermoelectric cooling (tec) modules featuring the company’s arctec structure, which includes a thermally conductive resin between the ceramic and copper on the cold side of the modules.

cui has released new peltier modules with its arctec structure. (cui, inc.)

according to an announcement from cui, “the elasticity of arctec’s resin layer allows for thermal expansion and contraction during the repeated heating and cooling of normal operation, which reduces stress on the elements, resulting in a better thermal connection, superior mechanical bond, and no marked drop-off in performance over time. high temperature solder and larger silicon elements are incorporated to enable faster and more uniform cooling.”

an article from all about circuits added, “the resin’s elasticity accommodates for the expansion and contraction that naturally occurs with temperature changes. cui claims that this gives components more longevity and allows better thermal connection overall.”

peltier tec modules work by placing semiconducting materials with differing electron densities in series and when voltage is applied it creates a temperature gradient between the two sides, which are layers of ceramic on top of copper. the hotter side is connected to a heat sink and, according to all about circuits, the gradient can be as much as 70°c.

cui insisted, “thanks to their reliable solid state construction, precise temperature control, and quiet operation, these thermoelectric coolers are ideally suited to high density, high power medical and industrial applications as well as refrigeration and sealed environments where forced air cooling is not an option.”

the company also said that the resin will combat thermal fatigue, which impacts the performance of the tec module. cui reported that the arctec structure demonstrated more than 50 percent improvement in cooling time compared to competitors.

to learn more about the arctec structure and see data about cui tests, click http://www.cui.com/catalog/resource/arctec-structure-improved-performance-and-life-span-in-peltier-modules.pdf.

|