|

researchers at rutgers university have combined graphene with a smooth, boron nitride crystal substrate and discovered a method for active cooling that has reached a power factor two times higher than that of previous thermoelectric coolers, according to a report on the school’s website.

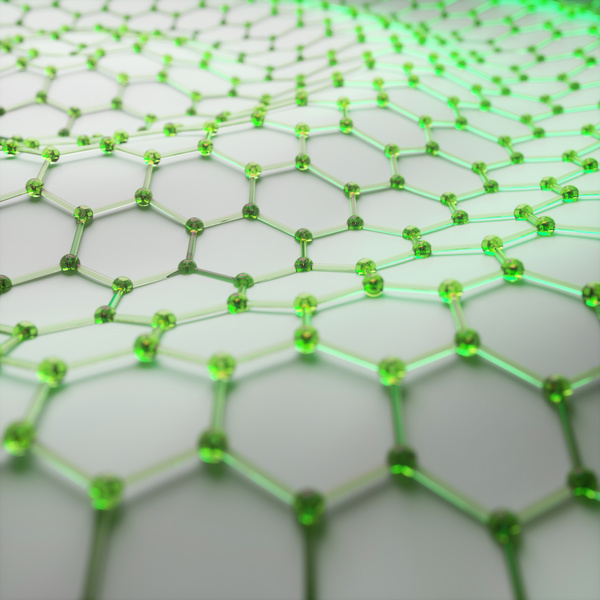

graphene, a one-atom-thick layer of graphite, consists of carbon atoms arranged

in a honeycomb lattice. (olivetree/shutterstock)

the researchers used devices made of boron nitride because silicon dioxide scatters electrons that carry heat away from the chips.

engineers applied voltage to the metal, which had hot and cold ends, and the voltage prompted electrons to carry thermal energy from the hot to cold ends. graphene’s natural electrical conductivity properties boosted this process.

the researchers insist that this technology could be used to cool chips in various electronic applications, particularly smaller devices with high component density such as smartphones.

the research was recently published in proceedings of the national academy of sciences. the report’s abstract read:

“fast and controllable cooling at nanoscales requires a combination of highly efficient passive cooling and active cooling. although passive cooling in graphene-based devices is quite effective due to graphene’s extraordinary heat conduction, active cooling has not been considered feasible due to graphene’s low thermoelectric power factor.

“here, we show that the thermoelectric performance of graphene can be significantly improved by using hexagonal boron nitride (hbn) substrates instead of sio2. we find the room temperature efficiency of active cooling in the device, as gauged by the power factor times temperature, reaches values as high as 10.35 w⋅m−1⋅k−1, corresponding to more than doubling the highest reported room temperature bulk power factors, 5 w⋅m−1⋅k−1, in ybal3, and quadrupling the best 2d power factor, 2.5 w⋅m−1⋅k−1, in mos2.

“we further show that the seebeck coefficient provides a direct measure of substrate-induced random potential fluctuations and that their significant reduction for hbn substrates enables fast gate-controlled switching of the seebeck coefficient polarity for applications in integrated active cooling devices.”

|