|

heat pipe assemblies from thermacore mean that thermal engineers can count on innovative, best-in-class thermal management solutions that offer industry-leading thermal performance, help control energy costs and maximize system life and reliability even under harsh conditions. efficient, cost-effective cooling from compact-size thermal solutions - even where space is limited - can be realized through a range of proven thermacore heat pipe assembly systems. these thermal technologies give engineers effective means to move heat for remote heat dissipation, low thermal resistance heat spreading from concentrated heat sources or isolated cooling to protect sensitive computer components, consumer electronics devices, transportation control systems and military systems, among many other applications.

heat pipes are composed of three basic parts, all of which thermacore has extensive experience in developing and delivering to the industry:

- a vacuum tight, sealed containment shell or vessel

- working fluid

- capillary wick structure

what are the containment vessels?

heat pipes can be constructed from a variety of different materials. thermacore has constructed heat pipes from aluminum, copper, titanium, monel, stainless steel, inconel and tungsten. the most common for electronics cooling applications is copper. the choice of heat pipe containment material is largely dependent on the compatibility with the working fluid.

how many kinds of working fluids are used?

thermacore has designed, developed and manufactured heat pipes using over 27 different working fluids. the heat pipe working fluid chosen depends on the operating temperature range of the application. working fluids range from liquid helium for extremely low temperature applications (-271°c) to silver (>2,000°c) for extremely high temperatures. the most common heat pipe working fluid is water for an operating temperature range from 1°c to 325°c. low temperature heat pipes use fluids like ammonia and nitrogen. high temperature heat pipes utilize cesium, potassium, nak and sodium (873–1,473°k).

| heat pipe working fluid | operating temperature range (°c) | heat pipe shell material |

| low temperature or cryogenic heat pipe working fluids |

| carbon dioxide |

-50 to 30 |

aluminum, stainless steel, titanium |

| helium |

-271 to -269 |

stainless steel, titanium |

| hydrogen |

-260 to -230 |

stainless steel |

| methane |

-180 to -100 |

stainless steel |

| neon |

-240 to -230 |

stainless steel |

| nitrogen |

-200 to -160 |

stainless steel |

| oxygen |

-210 to -130 |

aluminum, titanium |

| mid range heat pipe working fluids |

| acetone |

-48 to 125 |

aluminum, stainless steel |

| ammonia |

-75 to 125 |

aluminum, stainless steel |

| ethane |

-150 to 25 |

aluminum |

| methanol |

-75 to 120 |

copper, stainless steel |

| methylamine |

-90 to 125 |

aluminum |

| pentane |

-125 to 125 |

aluminum, stainless steel |

| propylene |

-150 to 60 |

aluminum, stainless steel |

| water |

1 to 325 |

copper, monel, nickel, titanium |

| high temperature heat pipe fluids |

| cesium |

350 to 925 |

stainless steel, inconel, haynes |

| nak |

425 to 825 |

stainless steel, inconel, haynes |

| potassium |

400 to 1,025 |

stainless steel, inconel, haynes |

| sodium |

500 to 1,225 |

stainless steel, inconel, haynes |

| lithium |

925 to 1,825 |

tungsten, niobium |

| silver |

1,625 to 2,025 |

tungsten, molybdenum |

how do the capillary wick structures work and what does thermacore offer?

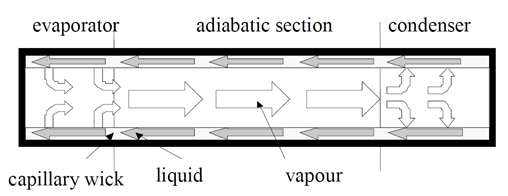

a wick structure or a specific envelope shape enables efficient capillarity. heat applied to the evaporator section by an external source is conducted through the pipe wall and wick structure where it vaporizes the working fluid. the resulting vapor pressure drives the vapor through the adiabatic section to the condenser, where it condenses, releasing its latent heat of vaporization to the heat sink. the capillary force created by the menisci in the wick pumps the condensed fluid back to the evaporator section. this provides the driving force for liquid in the heat pipe. the operating principle as described here is shown in the followin schematic:

thermacore manufactures all of the common wick structures, as well as the advanced wick structures. however, thermacore specializes in a "sintered powder metal" wick structure that allows the heat pipe to provide the highest heat flux capability, greatest degree of gravitational orientation insensitivity and freeze/thaw tolerance.

click here to learn more about thermacore heat pipe technology

click here to visit thermacore's main web site

a wick structure or a specific envelope shape enables efficient capillarity. heat applied to the evaporator section by an external source is conducted through the pipe wall and wick structure where it vaporizes the working fluid. the resulting vapor pressure drives the vapor through the adiabatic section to the condenser, where it condenses, releasing its latent heat of vaporization to the heat sink. the capillary force created by the menisci in the wick pumps the condensed fluid back to the evaporator section. this provides the driving force for liquid in the heat pipe. the operating principle as described here is shown schematically in figure 1.

|