|

a report, published in frontiers in heat pipes in 2015, by rahul s. borkar and pramod r. pachghare examined the effect of working fluid, filling ratio, and the number of turns on the performance of pulsating heat pipes (php).

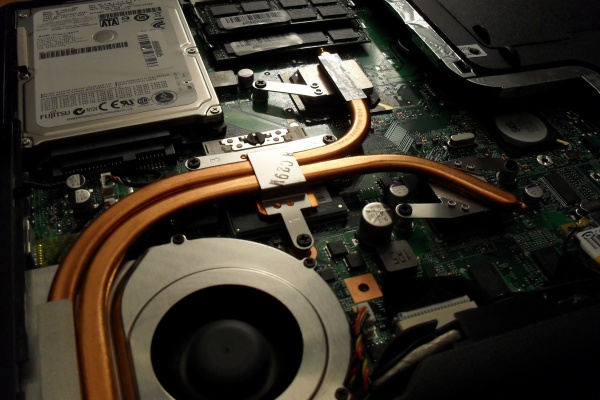

(wikimedia commons)

the researchers determined that fluids with a lower boiling point are more suitable for lower heating power and vice versa (higher boiling point fluids are better for higher heating power), the performance of the heat pipe depends on the behavior of the working fluid with respect to heat, and two-turn php has the best performance because of lower probability of phase recoiling and complete stop-over of the fluid motion.

the abstract from the report read:

“pulsating heat pipe’s (php) are one of the alternatives to conventional heat transfer technologies. first part of this paper, titled: thermohydrodynamic behavior of methanol charged closed loop pulsating heat pipe has given information about thermo-hydrodynamic operational characteristics such as; bubble nucleation and collapse, bubble agglomeration and pumping action, flow regime changes, pressure/temperature perturbations, dynamic instabilities, meta-stable non-equilibrium conditions etc. in the php.

“present paper, which is an extension of the previous work, it presents some more thermal results to highlight the effect of; thermo-physical properties of working fluid, filling ratio and number of turns on thermal performance of php. three different php loop has been made from six, four and two parallel glass tubes (i.e. three turns, two turns and one turn at evaporator section) forming adiabatic section, interconnected alternately by copper u tubes, having internal and external diameter 2 mm and 3.06 mm respectively. the length of evaporator, condenser and adiabatic section are 42 mm, 50 mm and 170 mm respectively.

“the experimentation conducted for different working fluids (water, ethanol, methanol and acetone), different filling ratio’s (30%fr, 50%fr and 70%fr) and different number of turns (one, two and three turns). the motto of present research is to understand the thermal performance in terms of thermal resistance of php in details. the result shows that, thermal resistance for all working fluid php’s rapidly decreases with increasing heating power up to 32w.

“for low heating power, working fluid (acetone) which has lower boiling temperature is best, but it cannot give the service for higher heating power. two turn php loop with methanol 50% volumetric filling ratio at more than 32w heating power with one directional flow circulation is the optimum operating condition of present research.”

read the full report at http://www.thermalfluidscentral.com/journals/index.php/heat_pipes/article/view/436.

|