|

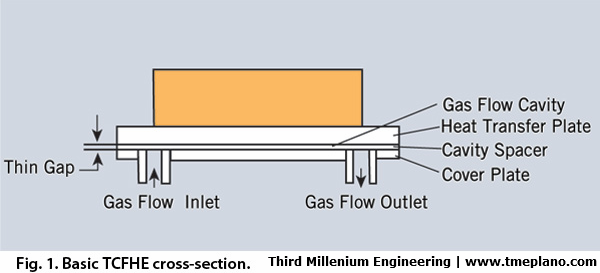

third millenium engineering has released a thin cavity fluidic heat exchanger, or tcfhe. the tcfhe is a simply constructed, small volume, high performance effective method for cooling critical electronic devices at the chip, board, module, and system levels. its high thermal performance originates from a very high velocity air flow, a very thin boundary layer, and high air utilization. it can efficiently and reliably cool critical regions in electronics at very low cost, in a small space, with high design flexibility, and with no concern for air leakage causing damage. the tcfhe resolves the conflict in high-speed electronics to completely seal a compact enclosure for shielding and packaging purposes while also removing high heat loads. the device is technically positioned between fan and heat sink methods and water cooling methods of cooling. when fan and heat sink methods or packaging constraints cannot obtain the needed thermal performance, the tcfhe is the next best choice over water cooling.

tcfhe technology is applicable from a micro to macro scale in power generation and distribution, defense, automotive, electronic, chemical, biomedical, and other industries. tcfhe structures can be used for air conditioning, refrigeration, combustion heaters, engines, motors, transformers, lighting, supercomputers, telecom, server farms, integrated circuits, and other devices. building infrastructure capital and energy costs can be reduced when such products are used, due to remote location of the gas flow source and heat exhaust. the gas used could be air, nitrogen, oxygen, freon, or similar gases at hot, room, or cold temperatures and can be direct or alternating pressure. it could be hot gas produced by internal or external fuel combustion or cool freon gas from refrigeration systems. the gas flow could originate from a gas compressor, compressed gas tank, ducted fan or blower, combustion chamber, or other pneumatic source. the technology also works well with liquids.

a full technical article with data is located at power electronics magazine, "thin cavity cooling of electronic circuitry"

for evaluation kits and more information, please contact dr. steve morra at third millennium engineering (972-491-1132, [email protected]). an evaluation kit based on the prototype is also available, as are consulting and development services.

|