|

the fraunhofer institute for organic electronics, electron beam, and plasma technology fep in dresden, germany recently announced that it has successfully developed oled (organic light-emitting diodes) electrodes from graphene, an atom-thin layer of carbon in a honeycomb pattern that has demonstrated remarkable properties including electrical conductivity.

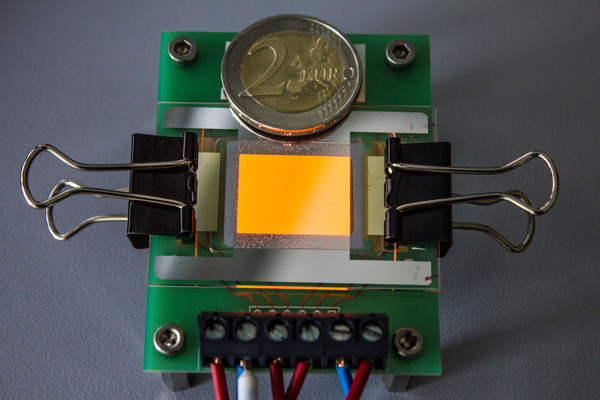

european researchers used graphene to create oled electrodes. (fraunhofer fep)

the breakthrough was part of the gladiator (graphene layers: production, characterization, and integration) project from the european commission that is expected to run through this coming summer and was tasked with optimizing the performance of cvd graphene sheets, increasing the size of cvd graphene batch reactors and improving the process in which graphene is transferred from cvd catalysts to substrates.

the gladiator program directly targeted the electrode market and, according to an article in ee times europe, includes spanish company graphene s.a., which makes the graphene electrodes, and british company aixtron ltd., which produces the cvd reactors.

according to a report on the fraunhofer website, the oled electrodes were created in a vacuum where a wafer plate of high-purity copper is heated to 800°c. a mixture of methane and hydrogen is added to initiate a chemical reaction.

the article explained, “the methane dissolves in the copper and forms carbon atoms, which spread on the surface. this process only takes a few minutes. after a cooling phase, a carrier polymer is placed on the graphene and the copper plate is etched away.”

the next steps in the project will be to minimize the impurities of the graphene when it is transferred to the carrier material.

“due to their flexibility, the graphene electrodes are ideal for touch screens,” the report concluded. “they do not break when the device drops to the ground. instead of glass, one would use a transparent polymer film. many other applications are also conceivable: in windows, the transparent graphene could regulate the light transmission or serve as an electrode in polarization filters. graphene can also be used in photovoltaics, high-tech textiles and even in medicine.”

|