|

chelmsford, mass. – december 18, 2012 – mercury systems, inc. (nasdaq: mrcy, www.mrcy.com), a best-of-breed provider of commercially developed, open sensor and big data processing systems for critical commercial, defense and intelligence applications, announced industry-leading innovations in thermal management for air-cooled, conduction-cooled and vita 48 subsystem chassis. these new solutions establish mercury as a forerunner in addressing the insatiable industry demand for more processing performance at the mezzanine, module and system levels. because more and more heat is generated by increasing levels of performance, discharging that heat out of today’s advanced computing solutions is more challenging than ever.

“our new thermal-management solutions are capable of dissipating tremendous amounts of thermal energy, while still meeting the same or smaller size, weight and power requirements for the overall solution,” said darryl mckenney, vice president of mercury’s engineering services team. “by understanding the thermal profile for each specific component that makes up a system, we created innovations in the mass transfer of thermal energy that work at the individual component, module and subsystem level.”

according to paul monticciolo, vice president and cto of mercury systems, “these new cooling technologies offer tremendous benefits for our customers that are looking to take advantage of current and future high-performance, high-power sensor processing technologies. we feel this technology will be quickly adopted into a wide range of applications; it’s another example of mercury innovation.”

air-cooled solution

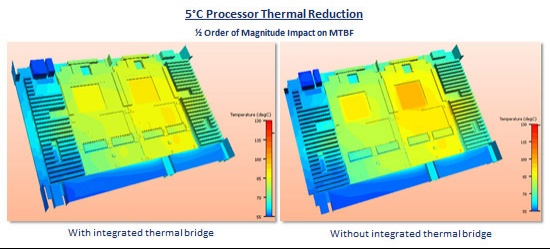

mercury’s improved air-cooled integrated xmc thermal solution addresses the need for a standards-based approach to draw heat away from today’s high-powered mezzanine cards, then onto the carrier module and ultimately out of the system in air-cooled environments. by adding “hooks” that connect to a thermal bridge between the card and module, the solution typically reduces mezzanine card temperatures by more than 5 degrees celsius. this results in a five-times improvement in mtbf (mean time between failures), while remaining compliant with the vita 48.1 mechanical specification for air cooling.

conduction-cooled solution

the new conduction-cooled solution tackles the industry’s need for an effective way to remove heat from mezzanine cards, while staying within the ansi/vita 20 requirements for conduction-cooled pmcs. by leveraging flexibility built into the specification, mercury’s advancement calls for the removal of the optional thermal ribs and the addition of a mezzanine cold plate that attaches to the carrier module. this creates a cooling area that is up to six times the area of the legacy solution. once implemented, maximum power levels of the mezzanine site that can be cooled are increased from 15 watts per mezzanine site to an impressive 50 watts.

air flow-by

mercury’s revolutionary air flow-by™ (afb) cooling techniques for vita 48.7/48.1 circuit card assemblies reduce module weight by more than 20 percent, reduce the power of a typical system by greater than 5 percent, and improve the mtbf by five times. the afb covers wrap around existing modules to create a sealed environment for protection against dust and contaminants, level-2 maintenance (l2m) and emi shielding (acts as an electrical faraday cage). the specially designed enclosures draw heat from the internal components to the exterior surface, where air is flowed across both sides of the module for maximum cooling efficiency. designed with today’s c-swap (cost, size, weight and power) requirements in mind, afb modules are offered in 1-inch pitch and attain industry-leading levels of thermal performance, providing over 200 watts per-slot of 6u cooling capacity — even when deployed in rugged environments. uniquely versatile, afb systems are capable of providing slots for conduction-cooled, while the afb modules can be used side by side with air-cooled modules, thus easing the transition from legacy solutions.

all three innovations (air-cooled, conduction-cooled and afb) are available today for high-powered radar, eo/ir, sigint and ew applications on rugged ground-based and airborne platforms. for more information on these offerings or mercury systems, visit mrcy.com/cool or contact mercury at (866) 627-6951 begin_of_the_skype_highlighting  (866) 627-6951 free end_of_the_skype_highlighting or [email protected]. (866) 627-6951 free end_of_the_skype_highlighting or [email protected].

mercury systems – innovation that matters™

mercury systems (nasdaq:mrcy) is a best-of-breed provider of commercially developed, open sensor and big data processing systems, software and services for critical commercial, defense and intelligence applications. we deliver innovative solutions, rapid time-to-value and world-class service and support to our prime contractor customers. mercury systems has worked on over 300 programs, including aegis, patriot, sewip, gorgon stare and predator/reaper. we are based in chelmsford, massachusetts. to learn more, visit www.mrcy.com.

forward-looking safe harbor statement

this press release contains certain forward-looking statements, as that term is defined in the private securities litigation reform act of 1995, including those relating to the products and services described herein. you can identify these statements by the use of the words “may,” “will,” “could,” “should,” “would,” “plans,” “expects,” “anticipates,” “continue,” “estimate,” “project,” “intend,” “likely,” “forecast,” “probable,” and similar expressions. these forward-looking statements involve risks and uncertainties that could cause actual results to differ materially from those projected or anticipated. such risks and uncertainties include, but are not limited to, continued funding of defense programs, the timing of such funding, general economic and business conditions, including unforeseen weakness in the company’s markets, effects of continued geopolitical unrest and regional conflicts, competition, changes in technology and methods of marketing, delays in completing engineering and manufacturing programs, changes in customer order patterns, changes in product mix, continued success in technological advances and delivering technological innovations, changes in the u.s. government’s interpretation of federal procurement rules and regulations, market acceptance of the company's products, shortages in components, production delays due to performance quality issues with outsourced components, inability to fully realize the expected benefits from acquisitions and divestitures or delays in realizing such benefits, challenges in integrating acquired businesses and achieving anticipated synergies, changes to export regulations, increases in tax rates, changes to generally accepted accounting principles, difficulties in retaining key employees and customers, unanticipated costs under fixed-price service and system integration engagements, and various other factors beyond our control. these risks and uncertainties also include such additional risk factors as are discussed in the company's filings with the u.s. securities and exchange commission, including its annual report on form 10-k for the fiscal year ended june 30, 2012. the company cautions readers not to place undue reliance upon any such forward-looking statements, which speak only as of the date made. the company undertakes no obligation to update any forward-looking statement to reflect events or circumstances after the date on which such statement is made.

# # #

contact:

robert mcgrail, director of corporate communications

mercury systems

+1 978-967-1366 begin_of_the_skype_highlighting  +1 978-967-1366 free end_of_the_skype_highlighting / [email protected] +1 978-967-1366 free end_of_the_skype_highlighting / [email protected]

mercury systems and innovation that matters are trademarks of mercury systems, inc.

|