|

in a quest to increase surface heat removal rates for electronics packaging, impinging jet cooling promises to be effective and inexpensive. most impingement cooling systems use open pipes. these are effective but have drawbacks such as high impingement forces on the target surface.

in the last 10 years radical nozzles have been shown in the laboratory to be novel and effective way to remove heat with negligible downward forces. compared with open jets, radial nozzles have high heat transfer capabilities. however, impingement jets produce only positive forces on the impingement surface. in contrast, radial nozzles produce negative forces on the target surface (mild suction).

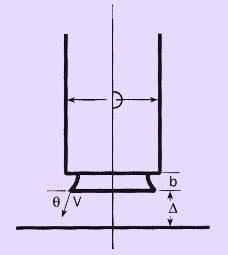

fluid issues from a radial nozzle in a radial direction. the radial jet typically reattaches to an adjacent surface due to viscous entrainment as show in fig. 1. a volume of lower-than-ambient pressure is generated under the nozzle with enhanced convection near the jet reattachment point. parametric experimental studies carried out to obtain both surface pressure distributions and convection coefficients and temperatures suggest that pressures depend upon the flow exit angle, reynolds number, dimensionless distance from the target surface, and nozzle diameter. the same parameters control surface heat transfer coefficients. overall, radial nozzles have been shown to remove up to 35% more heat than comparable open jets.

figure 1: radial jet.

radial nozzles are suited to situations for which impinging jets are used, such as electronics cooling, plastic film manufacturing and surface drying processes for paper, etc. radial nozzles have also been proposed for cooling enclosures, cavities and parallel plates that are commonly found in electric and electronic packaging. many of the applications require multiple nozzles.

in conclusion, radial nozzles compare very favorably with impinging jets for most electronics packaging cooling needs. these are still issues and aspects of radial nozzle design and operation that require further research. however, the present state of the art is such that the technology can be implemented with good success.

maurice j. marongiu, phd,

pe-mjm consulting services,

naperville, il

|